Relay Modules

Reversing contactors

DOLD solid-state reversing contactors are used where it is required to change the direction of rotation of three-phase motors, to start them softly and/or to monitor their load. Diverse diagnosis functions help to be kept always informed on the operational condition of the motor. Our devices save space, wiring expenses and cost.

Depending on model DOLD reversing contactors have either a reversing function (BH 9253 ) or a combination of reversing and current monitoring (BH 9255 ), or as in our new product (BI 9254 ) even a combination of reversing, softstart and active-power monitoring - all within a single device. There is a range of reversing contactors for motor power ratings up to 5.5 kW at three-phase 400 V available

- Long service life by wearless switching

- Improved operational reliability by integrated electrical interlock

- Time-saving: easy start-up by potentiometers, independent of software

- Easy overview on machine condition by diagnostics

- Cost-saving: the BI 9254 can often be used instead of a frequency converter

- Space-saving and easy-to-wire: all functions within one enclosure

DOLD reversing contactors - dead easily to handle

Electrical interlock

An integrated electrical interlock of the both directions of rotation ensures a troublefree and safe operation of your plants.

Exact zero-voltage switching

Switching of the semiconductors in the zero crossing of the alternating system voltage avoids EMC problems in neighbouring equipment.

No need of a very quick acting fuse

In principle a solid-state reversing contactor should be protected against short-circuit by a specific very quick acting fuse. This is to be selected on the basis of the semiconductor’s I²t value indicated in the data sheet. In practice, however, you can do without such a fuse. Then, the device must be protected by a commercially available motor protection switch.

Ready-to-use products for your applications

With optimized parameters such as heat sink size, EMC, heat dissipation etc. To select the product which is best suited for your application it is enough to know the current flowing through your load.

Quick and easy installation

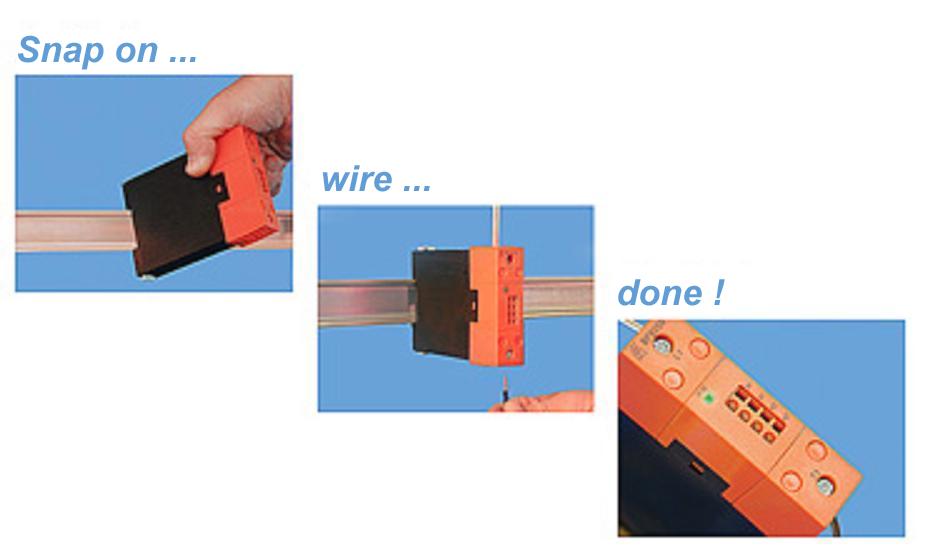

Simply snap these ready-to-use products on the top hat rail or screw them directly on the mounting plate.

Innovative technology

Switching of high load currents results in considerable heating of semiconductior contactors and relays. Inacceptable temperature rises may cause device failures after a time. To counteract this risk DOLD developed advanced technologies. Thanks to the DCB (Direct Copper Bonding) method it is possible to optimize heat dissipation in the power output element of the semiconductior contactors and relays and to ensure the operational reliability of your systems.

Application

- Extrusion and injection moulding machines

- Feed devices, e.g. in wood industry

- Servodrives in process technology

- Sewage treatment plants

- Carwash installations

- Gate controls

- Pumps

POWERSWITCH reversing contactors zero-voltage switching with integrated electrical interlock and heat sink, top hat rail mounting | ||||||||||

| Function | Load currents, 3- |

Load voltage, 3- AC [V] |

Auxiliary voltage AC [V] |

Digital triggering [V] | Temperature monitoring |

Signalling output |

housing Style: Width [mm] |

Type | ||

|---|---|---|---|---|---|---|---|---|---|---|

| DC | AC / DC | AC | ||||||||

| Standard | 3.6; 8.5; 11.5 | 24...500 | 24 | 230 | 400 | + | + | Switch cabinet: 45; 67.5; 112.5 |

BH 9253 | |

| with current monitoring | 3.6; 8.5; 11.5 | 24 ... 500 | 400 | 230 | + | + | Switch cabinet: 45; 67.5; 112.5 |

BH 9255 | ||

| with softstart and active- |

11.5 | 400 | 24 | + | + | Switch cabinet: 90 |

BI 9254 | |||