Relay Modules

Semiconductors relays / contactors

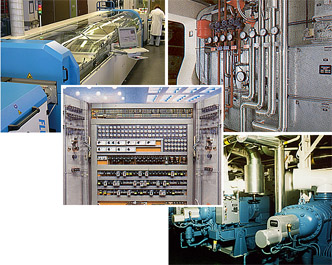

- Solid-state contactors proved to be good in industrial applications where high switching frequencies or high switching cycles are required. With their long service life and wearless switching they solve switching and control tasks in specific applications in an extremely economic manner. Application areas include:

- Extrusion and injection moulding plants

- Heating controls

- Soldering lines

- Hot-melt glueing robots

- Oven controls

- Three-phase motors

- Lighting controls

- Materials handling installations

- Dispensing equipment

- Packaging machines

- Copying equipment

- Self-service automats

- Traffic lights

|

Ready-to-use products and easy installation: |

|

Long service life |

|

Long service life |

|

Excellent EMC properties |

|

Innovative technology DCB technology optimizes heat dissipation |

| |

Low space requirements |

| |

Customer-specific solutions and special-purpose variants |

| |

Suited for high switching frequencies |

| |

Low trigger current |

| |

|

| |

High I²t |

DOLD semiconductior contactors and relays dead easily to handle

Ready-to-use products for your applications

With optimized parameters such as heat sink size, EMC, heat dissipation etc. To select the product which is best suited for your application it is enough to know the current flowing through your load.

Quick and easy installation

Simply snap these ready-to-use products on the top hat rail or screw them directly on the mounting plate.

Innovative technology

Switching of high load currents results in considerable heating of semiconductior contactors and relays. Inacceptable temperature rises may cause device failures after a time. To counteract this risk DOLD developed advanced technologies. Thanks to the DCB (Direct Copper Bonding) method it is possible to optimize heat dissipation in the power output element of the semiconductior contactors and relays and to ensure the operational reliability of your systems.

Semiconductor contactors/relays POWERSWITCH Semiconductor relay: for screwing on the heat sink. Semiconductor contactors: with integrated heat sink, top hat rail mounting | |||||||||||||

| Function | Load current [A] | Load voltage AC to [V] | Auxiliary voltage DC [V] |

On/Off Input Control [V] | Analog Input Control | Temperature monitoring |

Signalling output |

Width [mm] |

Type | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 pole | 2-polig | 3-polig | DC | AC / DC | AC | ||||||||

| Semiconductor relay | 25; 50; 100; 125 |

600 | 4…32 | 18…36; 85…265 | 45 | ||||||||

| Semiconductor relay/ - |

2 x 32; 2 x 48 |

480 | 18…30 | 45 | PH 9260.92 | ||||||||

| Semiconductor relay/ - |

25; 50 | 480 | 4...20 mA | 45 | PH 9260/042 | ||||||||

| Semiconductor relay with load circuit monitoring |

40 | 480 | 32 | 20…32 | 45 | PH 9270 | |||||||

| Semiconductor relay/ - current measurement |

25; 50 | 240 | 20…32 | 45 | PH 9270/003 | ||||||||

| Semiconductor relay/ - for ohmic loads |

to 88A | 600 | 4...32 | 18...30 | 100...230 | 22.5 | PK 9260 | ||||||

| Semiconductor contactor | 10; 25; 50 |

6.5; 15; 25 | 5; 10; 15 | 480 | 24; 110...230 |

+ | + | 22.5; 45; 90 | BF 9250 | ||||

| Semiconductor contactor | 10; 25; 50 |

6.5; 15; 25 | 5; 10; 15 | 480 | 4…32 | 22.5; 45; 90 | BF 9250/_ _8 | ||||||

| Semiconductor contactor with temperature monitoring | 10; 25; 50 |

6.5; 15; 25 | 5; 10; 15 | 480 | 24 | 4…32 | + | + | 22.5; 45; 90 | BF 9250/001 | |||

| Semiconductor contactor with burst control | 10; 25; 50 |

480 | 24 | 4…20 mA / 0…10 V |

+ | 22.5; 45; 90 | BF 9250/002 | ||||||

| Semiconductor contactor with optimized pulse cycles | 10; 25; 50 |

480 | 24 | 4…20 mA / 0…10 V |

+ | 22.5; 45; 90 | BF 9250/042 | ||||||

| Semiconductor contactor with load circuit monitoring |

10; 20; 40 |

400 | 9,6…270 | + | + | 45; 67,5; 112.5 | BH 9251 | ||||||